Quantum batteries could revolutionise energy storage and find a place in the car of tomorrow if their technical challenges are overcome. A quantum battery is a cutting-edge technology that leverages the principles of quantum mechanics to store energy. Unlike traditional batteries, which are charged by electron flows, quantum batteries utilise photons for energy storage. Although still in the early stages of development, quantum batteries hold the potential to be significantly more efficient and powerful than their electrochemical counterparts. Quantum batteries differ fundamentally from traditional ones. While conventional batteries rely on chemical reactions to charge and discharge energy, quantum batteries are powered by quantum entanglement — a phenomenon where particles remain interconnected regardless of distance. Ju-Yeon Gyhm, a quantum researcher at Seoul National University, explained to Giz Modo, a tech news service, that these batteries consist of multiple quantum cells that function as a single entity. The challenge lies in maintaining the quantum properties for extended periods. A major hurdle for quantum battery technology is sustaining quantum states outside controlled research environments. Just as quantum computers face issues with maintaining their delicate states, quantum batteries must overcome similar obstacles. Achieving this would require breakthroughs akin to discovering a room-temperature superconductor.

Korea hybrids

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Amid all the BEV hype, hybrids have quietly been doing very well in Korea. On a trend sales basis, represented by the 12-month rolling sum, Korean sales of Zero-Emission Vehicles (ZEVs) i.e., Battery Electric Vehicles (BEVs) and Fuel Cell Electric Vehicles (FCEVs), fell by 17% over the last year while sales of HEVs (full- and plug-in hybrids) increased by nearly 45%, as of April 2024. ZEV sales, 97% of which are BEVs, have been slowing since the second half of 2023, while HEV sales have been gaining greater growth momentum from early 2023. Sales of BEVS have decreased over the last year or so, but hybrid sales have increased more than BEV losses.

ASEAN data dump

ASEAN Light Vehicle (LV) sales declined by 9.3% year-on-year (YoY) to 963k units from January to April. Malaysia and the Philippines were the only countries to experience positive sales growth, while Indonesia, Thailand, and Vietnam continued to face weak demand.

Global sales up

The global light vehicle market continued to show a modest improvement in May, according GlobalData. The selling rate stood at 88 million units/year in May, a modest improvement on the previous month. With 7.2 million vehicles sold last month, this was a 1.0% improvement year-on-year (YoY), with year-to-date (YTD) sales up 3.4%. Key markets, China and the US, benefited from improved selling rates versus the previous month. In Europe, there was little change for the West of the region in its MoM selling rate evolution, while Eastern Europe made progress, with the latter once again supported by recovery in Russia. In Japan, the selling rate declined notably as supply issues persist.

Diesel flat

May’s diesel share of Western Europe’s car market still hovers around 15%, according to figures released by GlobalData. April’s diesel share of new car sales in the region is confirmed at 15.1% with a slight fall in May (subject to slight revision) leading to a provisional reading of 14.8% and year-on-year decline of just 1.9 percentage points.

China market

The next few years will be pivotal in determining how the Chinese PV market positions itself in the global automotive industry landscape. The Chinese Passenger Vehicle (PV) market has been on a steady growth trajectory in 2024, despite intensifying internal competition. After a brief dip in February due to the Chinese New Year holiday, which resulted in fewer selling days, sales rebounded in March and April, returning to a consistent growth pattern. Domestic PV sales, excluding exports, saw a 5.4% year-on-year (YoY) increase in March and a 4.2% YoY growth in April. Cumulatively, from January to April 2024, PV sales reached 6.3 million units, reflecting a 5.5% YoY increase. The production side has shown even more robust growth, with a commendable 9.0% YoY increase, amassing 7.6 million units over the same period. This suggests that the production growth is outpacing sales volume, indicating potential market saturation or a buildup of inventory.

Decarbonising trucks

While many in the automotive world focus on decarbonising day to day vehicles, others are looking into the medium and heavy-duty truck space. Although making up a small percentage of vehicles on the road, sitting at 5%, medium and heavy-duty trucks are responsible for 25% of transport greenhouse gas emissions in the US. With emissions and decarbonisation at the forefront of the automotive industry’s mind – what can be done to reduce the sector’s carbon impact. On a mission of assist the industry look for ways to decarbonise, EV Realty, a company who develops, deploys, and owns grid-scale charging infrastructure, is focusing in on medium and heavy-duty trucking and helping build out infrastructure while developing a platform that it says can power commercial fleets. We spoke to EV Realty CEO, Patrick Sullivan, to discuss the Hub Based Strategy vs the Transportation Corridor strategy as well as future predictions for the heavy-duty EV space.

Autonomous

Autonomous driving technology is still facing major challenges in terms of getting close to the adoption of fully autonomous vehicles on public roads. Autonomous driving technology is progressing, presenting itself as an advanced technology that will be shaping the future competitive frontier in the automotive space. However, although the technology is developing amongst OEMs and specialist tech providers, many feel that the technology has a long way to go in the development phase. From infrastructure, technology support and cybersecurity risks, autonomous driving technology is still facing several hurdles along the way to much wider adoption. Autobrains, a leading AI company in the automotive industry, says it offers solutions for the next generation of vehicles and mobility – providing safer, superior performance at lower energy consumption and lower cost. We spoke to founder and CEO of Autobrains, Igal Raichelgauz, to learn more about the challenges facing autonomous vehicles and to discuss what more can be done to support the development of this advanced technology.

Sealants

Carbon emissions and cost. The automotive industry is looking for ways to reduce both when and where it can. Could the use of adhesives and sealants in manufacturing help? The automotive industry uses a variety of sealants and adhesives within the car manufacturing process. These perform roles that vary from securing pieces together to ensuring seams stay put. One huge benefit of utilising sealants is cost and emissions reduction when compared to alternatives in some applications – such as welding, which is a relatively costly and emissions-heavy process. Sunstar Engineering works with automotive manufacturers worldwide. Its operations include a factory specialising in innovative lightweighting sealants and adhesives for the automotive market including special adhesives for electronic components. It says these components are helping automotive manufacturers create lighter, more durable, and efficient vehicles. We spoke to Nicholas Huff, manager, new technology group, Sunstar Engineering Americas, and Stephen Howe, senior director, technical operations, R&D, Sunstar Engineering Americas, to learn more about the benefits of adhesives as well as to discuss how they work with clients to achieve goals.

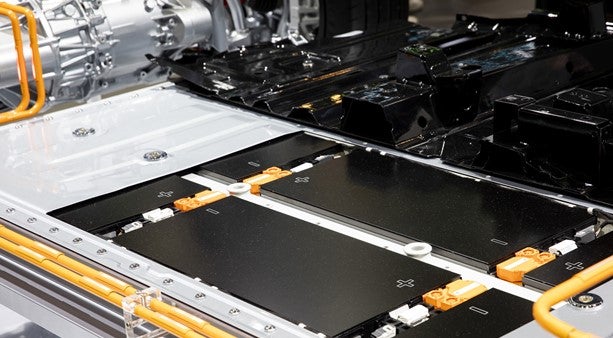

Battery bubble burst?

Sweden’s Northvolt, the lithium-ion battery maker is reviewing its plan to build a new plant in central Sweden, Reuters reports. It comes after Swedish business daily newspaper Dagens Industri reported the firm was cancelling the project. Northvolt said it has not ‘reached any decisions’ and it was conducting a strategic review of the site, in Borlange.

China closing

Nissan is shutting down its car plant in the eastern city of Changzhou, Jiangsu province in China, Nikkei reported, as the automaker tries to trim overcapacity amid a sales slump in the increasingly price competitive market. The report said Nissan had been making the Qashqai SUV at Changzhou. Plant capacity is around 130,000 units annually, accounting for more than 8% of Nissan’s total production capacity in China. Today, Friday, was the last day of operation.

Smart talking VWs

Volkswagen models with the new generation infotainment system are now also equipped with artificial intelligence (AI) of ChatGPT. The AI based research tool is available in all new vehicles in the ID. EV family, as well as the Golf, Tiguan and Passat. It can be accessed using the IDA voice assistant and offers a range of new options that go far beyond the voice control previously available. For example, customers can now have search results read out to them, and can interact with the car using natural language.

Toyota parts shortage

Toyota has said it will halt six production lines at five of its plants in Japan, Reuters reports. The automaker attributed the pause to a parts shortage, and said it would decide if it would resume production at the end of the week. No further details were given on which plants are affected or what parts are involved.

Have a nice weekend.

Graeme Roberts, Deputy Editor, Just Auto