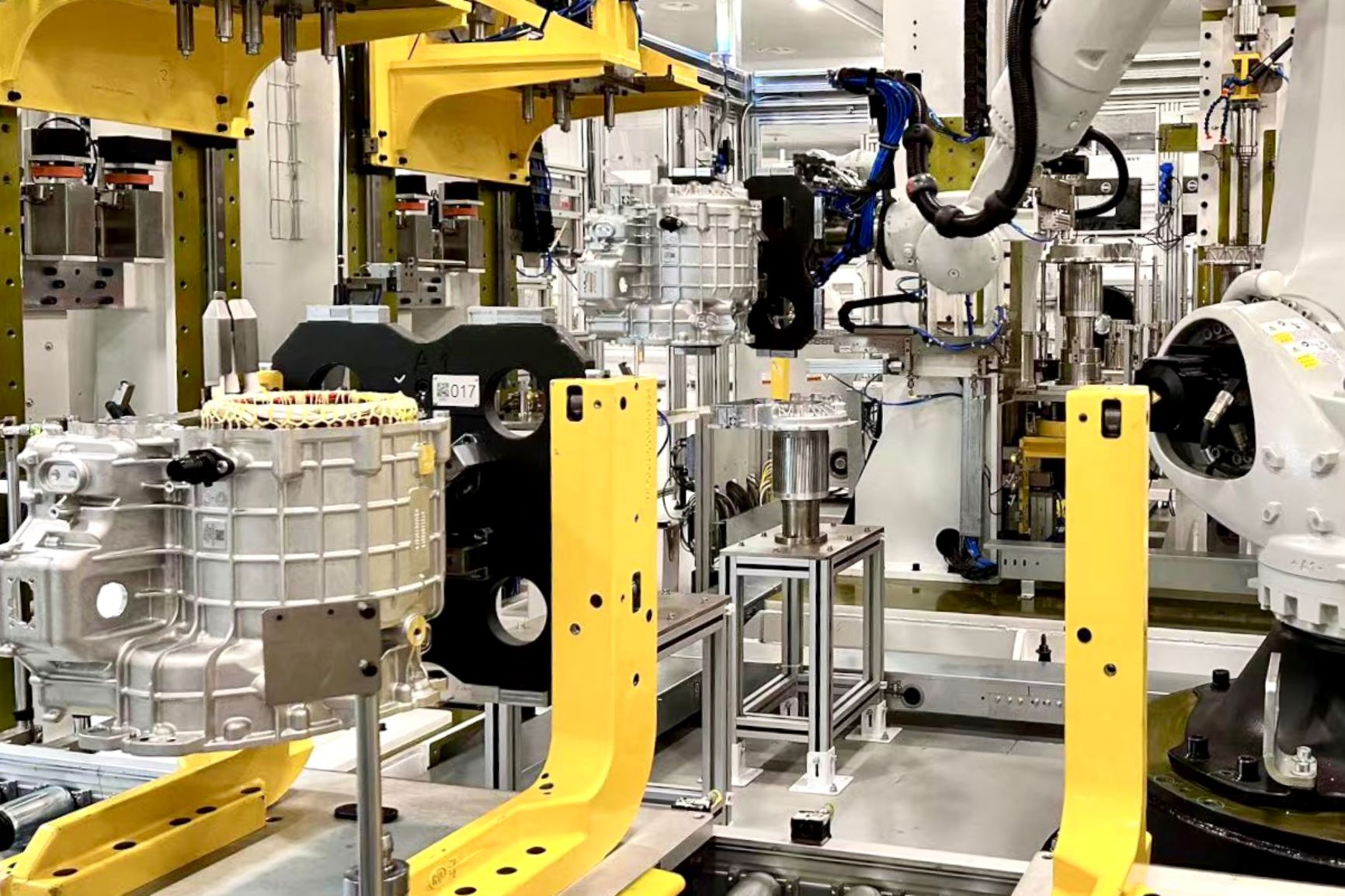

Comau has provided equipment to automate production of new Nio electric drive systems.

The system allows co-line production for induction and permanent magnet motors and includes primary lines such as e-motor assembly, gearbox manufacturing and inverter assembly as well as end of line testing.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

It is designed for annual capacity of 1m units, to be used in electric sedans, coupes and SUVs, as well as select models of the Nio sub-brand Alps.

Comau said the system allows optimal flexibility and scalability, allowing the customer to adjust production environment to accommodate different processes as needed for new products.

Comau collaboratively developed a new adapter with zero point positioner with Nio’s e-drive engineers. This effectively unifies design, process, and control standards, allowing different assembly requirements to be met while maintaining maximum flexibility.

The system has 3D vision guided robots, AGVs for autonomous material supply, and automatic tool end loading while the use of quadnocular stereovision 3D cameras overcame limitations of vision guidance technology in terms of field of view and gripping range, allowing automatic part positioning and assembly in addition to “excellent repeatability”.

“Considering the rapid growth of new energy vehicles in China, a market in which production rates and sales volumes in the first half of 2023 have increased by 42.4% and 44.1% respectively, the demand for electric drive systems has increased significantly,” said Jeff Yuan, Comau’s APAC head.