Posco International, the trading and energy unit of South Korean steelmaker Posco Group, announced it planned to build a US plant to produce permanent magnets for electric vehicle (EV) drivetrains in partnership with Star Group Industrial, a South Korean company focused on rare earths.

In the last few years, Posco has expanded rapidly in the fast growing EV supply chain, having made significant investments in mining and processing of key minerals uses in EV battery cathodes and anodes such as lithium, nickel, cobalt and graphite.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

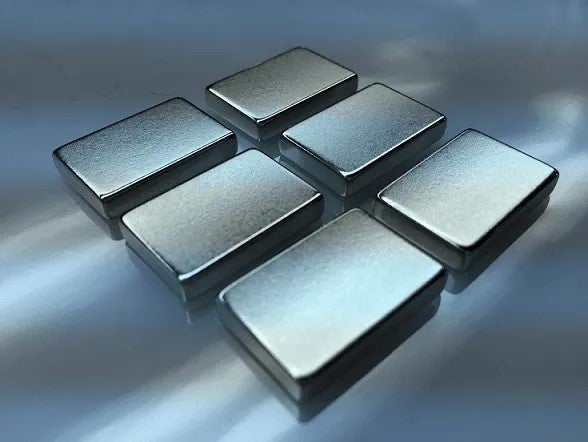

Permanent magnets use rare earths and are essential components of EV motor cores. Magnet quality affects motor performance.

Posco Mobility Solution is a significant global manufacturer of motor cores.

Posco and Star Group were understood to be in discussions with Texas, Tennessee and Arizona state governments for a plant location. The two wanted to jointly invest KRW300bn (US$220m) in a factory with initial production capacity for 3,000 tons of permanent magnets per year, rising to 5,000 later on, enough for 2.5m EVs.

Expected customers for US made magnets are Hyundai Motor Group US operations, General Motors, Ford and Stellantis.

The global permanent magnet segment is currently dominated by Chinese producers Zhongke Sanhuan and Yantai Dongxing Magnetic Materials.