Modern extensometry for a data-driven world

The performance capabilities of the VectorExtensometer practically renders traditional, mechanical tools obsolete.

Tinius Olsen provides a range of material testing services for the Automotive Industry.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Tinius Olsen is the leading global specialist manufacturer and supplier of strength and performance test equipment for automotive materials, components, and devices. The company’s machines are used for quality control in support of manufacturing processes, research and development, and education. The company also provides a wide variety of tooling and accessories, including bespoke grips and assemblies, as well as temperature chambers and furnaces.

Tinius Olsen engineers design and manufacture hardware, firmware, and software. They are actively involved in standards organisations, including ISO, ASTM, and EN. 30% of the company’s engineers are engaged as committee chairs or senior members, and all customers have access to the company’s experts and technologists. Through this proactive input in developing international standards, Tinius Olsen complies with all relevant standards to meet its clients’ strategic needs.

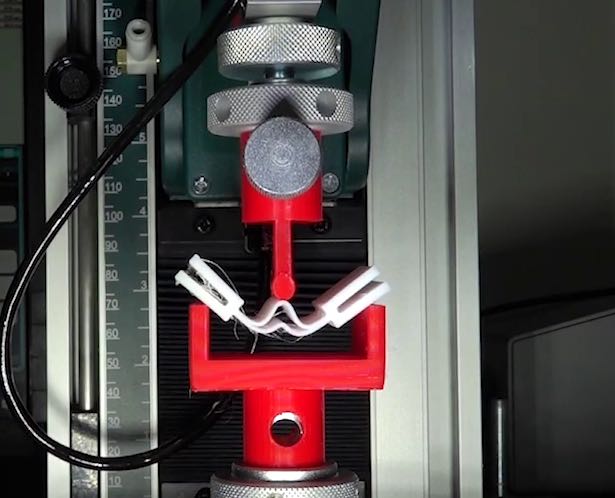

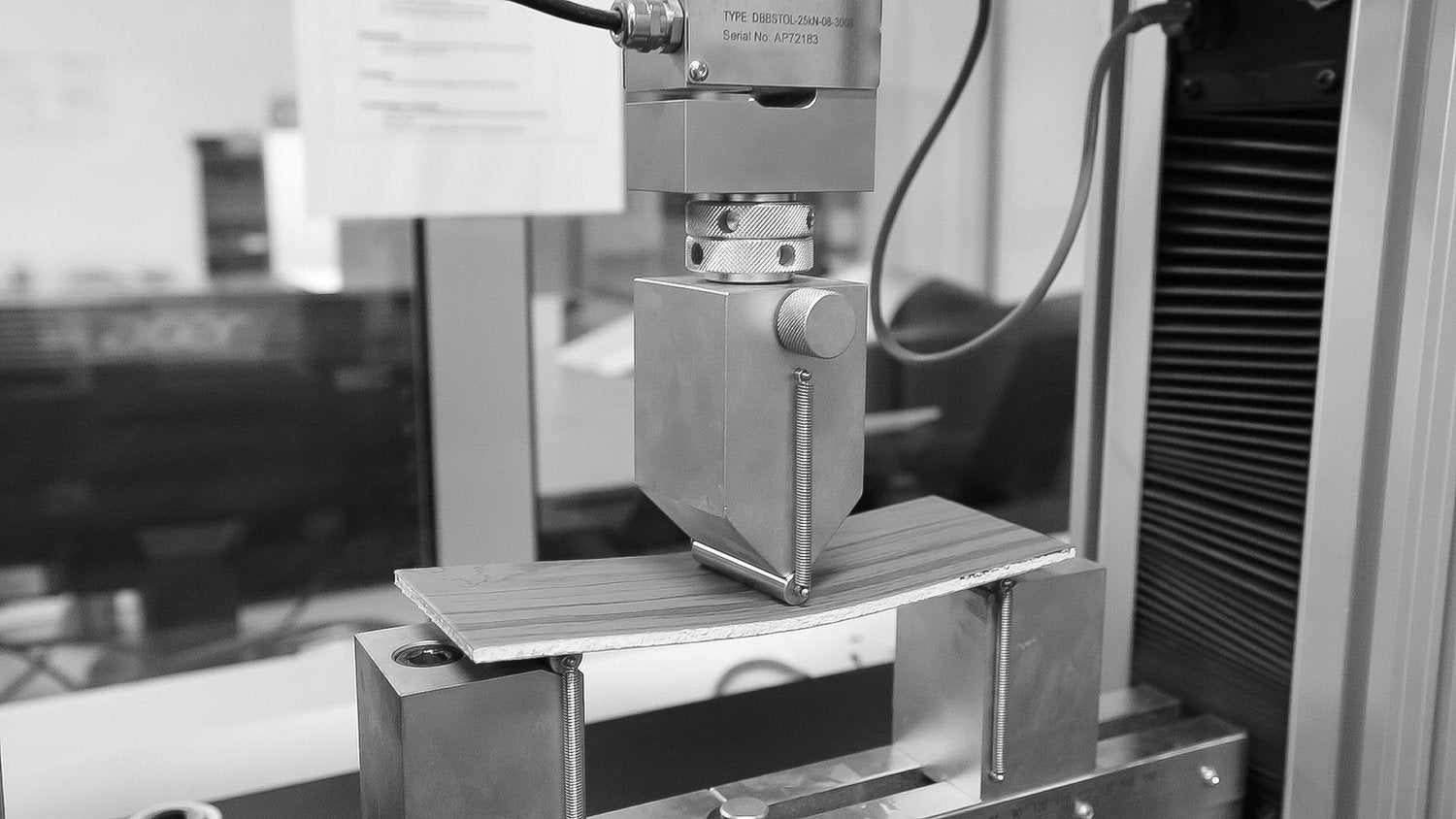

Tinius Olsen’s equipment is used to test the behaviour of a material or component when it is exposed to forces in tension, compression, flexion, or impact to determine the strength, hardness, impact resistance, and flow rate. Its products include static testing equipment for either tensile or compression, using a single frame, hardness, pendulum impacts, melt flow indexers, heat distortion, Vicat, and more to suit a variety of strength test needs. In accordance with key international testing standards, Tinius Olsen designs and implements its equipment to meet ISO, ASTM, and ES standards.

Elements of automation have become a key part of Tinius Olsen’s systems, ranging from autogripping to full robotic systems. Everything is designed to support productivity, repeatability, and traceability. To make material testing easier, the company has developed scalable technology blocks to automate tensile, compression, flexural, impact, melt flow, and hardness tests. Its systems can handle low milli Newton forces to thousands of kN of force and process approximately 30 to 250 tests per day.

Horizon is a fully network-capable platform using an SQL database, which is able to meet even the most rigorous compliance and traceability needs of those in the aerospace, automobile, and consumer product industries. It is future-proofed through Tinius Olsen’s status as a formal software developer and includes built-in diagnostics and support tools, making operation easier and more efficient for users.

Tinius Olsen’s Horizon testing software links the material or component being tested with the process that requires the test results. The software can manage multiple operators and allows users to simultaneously view the results. Test methods are defined according to international standard uses and the software also captures high-speed data to display real-time results throughout the test. When the test is completed, it instantly compares the results with the pre-defined pass/fail limits then alerts and reports the results to the required operators.

Tinius Olsen is constantly innovating and evolving in the testing sector. Vector is a step change in extensometer technology, capable of replacing multiple contacting and non-contacting sensors with a single, industry specific instrument.

Integrating adaptive AI capabilities with optical hardware, Vector reduces test throughput times and complexity, automating the process of capturing strain while improving measurement accuracy, data consistency, and operator safety. Efficient, simple, and reliable, Vector has advanced functionality and offers extremely rapid ROI.

Tinius Olsen was born in Kongsberg, Norway in 1845. He graduated from the Horten Technical School in 1866 and became the foreman of the machine department at a naval machine shop. At age 24, he left for the US and arrived in Philadelphia, where he found employment with William Sellers and Co as a designer.

Olsen soon moved to a small workshop run by the Riehlés brothers and designed the first boiler-plate tensile testing machine for paddle steamers working the Mississippi river.

The new device was successful, and Olsen was invited to take over the workshop, becoming director of the Riehlés plant in 1872. His pioneering contributions to the emerging field of materials testing included vertical and horizontal machines for materials used in bridge construction, locomotive boilers, and other industrial goods.

He left Riehlés in late 1879, wanting to design a universal testing machine that would be revolutionary at the time. He made the drawings for the new machine and, on 2 February 1880, Olsen submitted a patent application for a “new and useful improvement in testing machines,” which was granted on 1 June 1880 and the ‘Little Giant’ was born. The Tinius Olsen Testing Machine Company was established later that year.

The Little Giant won gold medals at industrial expositions in Cincinnati and Atlanta in 1881. By 1882, Olsen had received an order for the first 200,000lbf testing machine ever made. Olsen continued to innovate in the testing machine field for decades thereafter. He retired from the company in 1929 and died in 1933.

Tinius Olsen works with partners worldwide, including universities and colleges, to develop and research new materials and processes. The company has manufacturing plants in the US, UK, and India, and a showroom in China. It also has an extensive sales network that covers many countries around the world.

The performance capabilities of the VectorExtensometer practically renders traditional, mechanical tools obsolete.

The rapid pace of expanding manufacturing demands is saddled against a company's ability to increase yield.

How to fit automated materials testing into your manufacturing.

The race to meet net zero is hotting up as the development of alternatives to battery power start to come online. Tinius Olsen is currently supporting one of them alongside the UK’s leading developer of hydrogen fuel cell technology, Intelligent Energy.

Cincinnati State Technical and Community College, which is celebrating its 50th anniversary this year, provides student-focused, accessible, high-quality technical and general education, academic transfer, experiential and cooperative education and workforce development.

The race to meet net-zero is hotting up as the development of alternatives to battery power start to come online. Tinius Olsen is currently supporting one of them alongside the UK’s leading developer of hydrogen fuel cell technology, Intelligent Energy.

This new discovery from the wings of a flying beetle sheds light on how a wing changes shape in flight using an unusual bell shaped structure, which is compliant in one direction but almost ten times stiffer in the opposite direction.

RMK Industries supplies to more than 25 countries around the world. Their primary stronghold is the Middle Eastern, Asian, and African markets and they are trusted by internationally renown contractors, consultants, and architects.

How bottles and jars are changing the face of civil engineering projects and the testing needs behind it all.